If you’ve ever been wheeled into surgery, you probably noticed a lot of stuff. You most likely missed the one thing that mattered most though. Whether the tools being used were sterile, complete, and actually ready for surgery. That behind-the-scenes job belongs to sterile processing technicians.

Some careers are front-stage, shiny, and loud. This one is… none of that. Yet it’s one of the most essential and steady jobs in healthcare. And strangely, it’s also one of the least understood.

It’s Not Just “Cleaning Tools”

Just hearing the job title, you might picture someone “washing tools.” That’s like hearing “pilot,” looking at a cockpit deciding the job is “turning knobs.” Sure, knobs get turned. But the real work is precision, the process, and accountability; making sure every instrument is inspected, assembled correctly, documented, and ready to be used on a real living person being without failure.

Sterile processing is part sanitation, part quality control, part logistics, and part catch the tiny mistake before it becomes a huge problem. It is hands-on work, but it’s also extremely detailed work. The kind where being slightly careless can turn into a serious issue fast.

What You’re About to Get

So here’s the whole thing: the parts that sound impressive, the parts that sound boring (there are some), the parts no one tells you until you’re already inside the department thinking, “Why does every tray have fifteen versions of the same clamp?” And, of course, the practical stuff: pay, training, certification, opportunities, and how to tell whether this path fits your personality, or will stress you into dust.

What Sterile Processing Technicians Actually Are

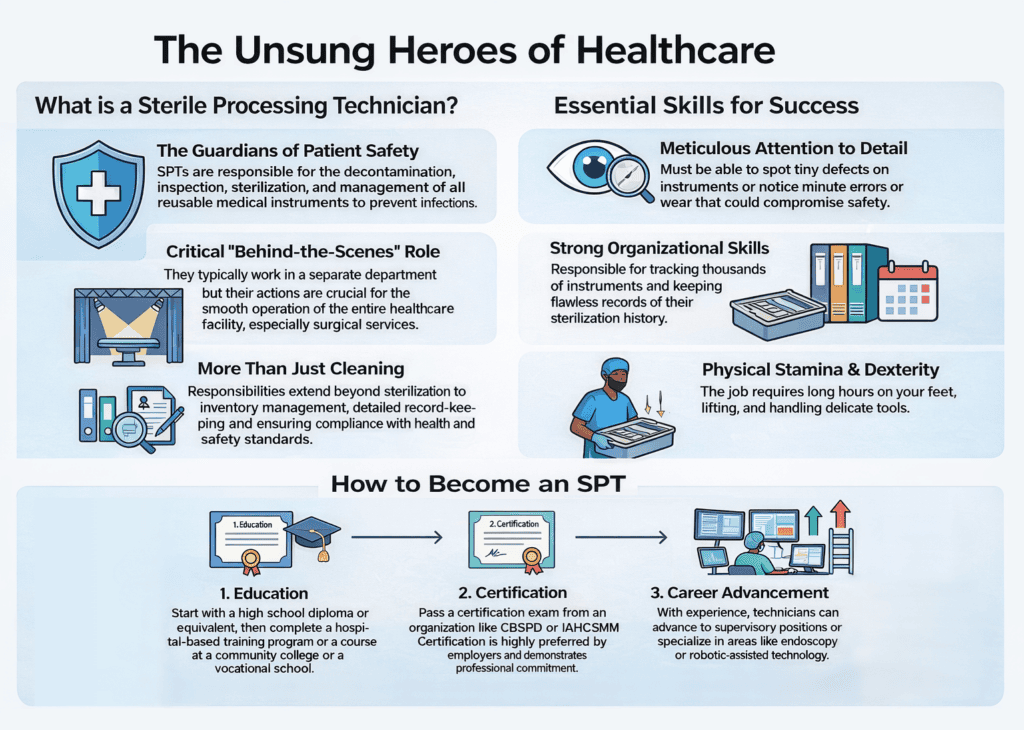

Sterile processing technicians (a.k.a. sterile processing department technician – SPD) are responsible for cleaning, inspecting, assembling, sterilizing, and correctly distributing the surgical instruments a facility uses. Every scalpel, retractor, orthopedic drill attachment, and tiny labeled screw passes through this department before it ever touches a patient.

That means you’re doing more than just “washing tools.” You are making sure each instrument is the right one, in the right tray, in the right condition, and truly sterile… with documentation to back it up. One missing clamp or one instrument that is still grimy in a hinge can delay a case, cause rework, or even create a safety risk.

A Quiet Job That Keeps It All Together

You are basically the firewall between patients and infection. The work is technical, physical, and (surprisingly) satisfying when everything clicks: trays built correctly, loads run cleanly, carts staged on time, and the operating room never has to wonder if they can trust what shows up.

If sterile processing slips, the whole facility feels it. Surgeries get delayed. Surgeons wait. Nurses scramble. Phones start ringing. People get tense fast because the clock is always running in an operating room.

Why the Field Keeps Growing

From the outside, a lot of people don’t realize how fast the sterile processing technician’s demand is rising. It’s mostly because the work stays invisible until something goes wrong. But healthcare never sleeps, and sterile processing is tied directly to surgical volume, so it grows whenever:

- More people need procedures

- More outpatient surgical centers open

- Infection control standards tighten

- Hospitals expand robotics and specialty surgeries

- Retirements outpace incoming trainees

Even in economic downturns, the demand tends to stay steady. Surgeries don’t wait for the economy to act a certain way. This is one of the rare healthcare paths where job security can be strong without requiring a massive investment in schooling.

Why the Job Has “Weight”

Even on boring days, you’re “always-on,” one mistake can seriously affect patient safety, infection control, and even hospital efficiency… all at once. You’re at the intersection of precision and urgency: moving quick, but never sloppy. On those less exciting days, you’ll still feel that responsibility. Because the department is built on one rule: “Close enough is not close enough.”

A Realistic Day as a Sterile Processing Technician

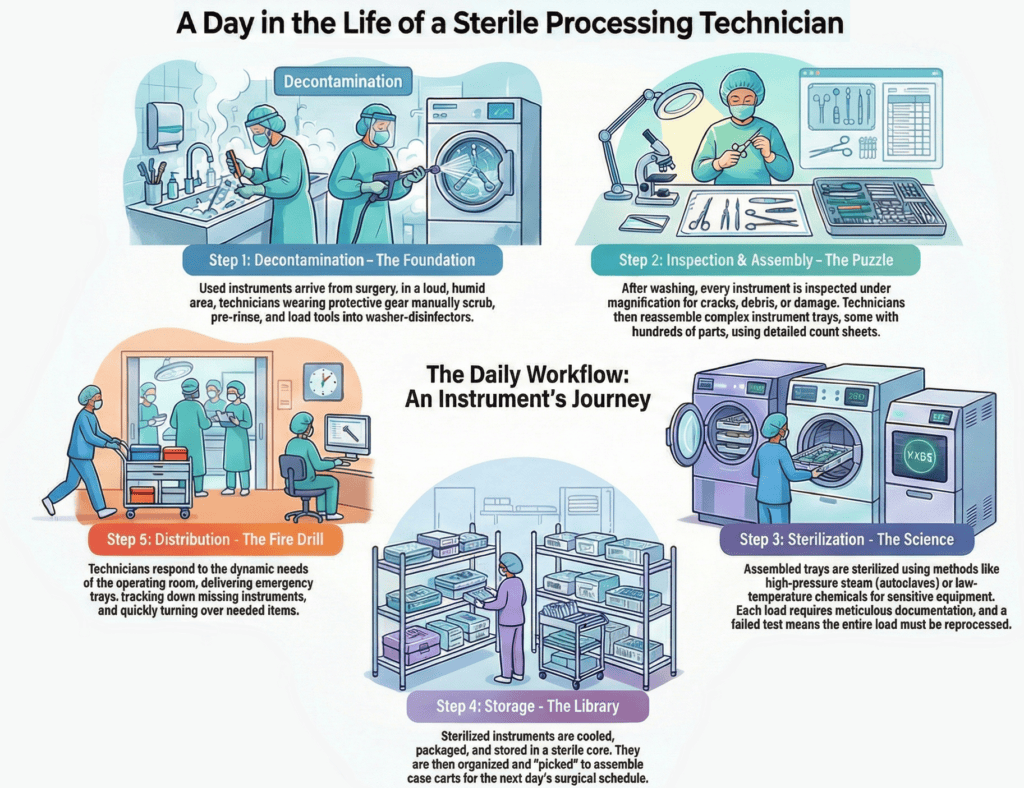

Sterile processing work runs in a loop. Instruments come in contaminated, move through cleaning and inspection, get sterilized, then go back out to support the next case. Some parts feel intense. Some parts feel repetitive; but it’s the good kind of repetitive, the kind that lives because “close enough” is how mistakes happen.

What the Job Actually Looks Like

1. Decontamination: The Start of Everything

Dirty instruments arrive from surgery. Sometimes they’re neatly stacked. Sometimes they’re… not. In decontamination, you:

- Take all instruments apart

- Pre-rinse and flush lumens (the tiny channels inside certain tools)

- Load washer-disinfectors

- Scrub debris off complicated pieces

- Soak, rinse, drain, sort

Heat, protective equipment, humidity, loud noise… This area is far from glamorous. But it’s the foundation. If decontamination is sloppy, everything downstream turns into a mess.

2. Inspection and Assembly: The Puzzle-Solver Stage

Once instruments exit the washers, you inspect them like you’re looking for problems before anyone else has to deal with them:

- Every hinge

- Every tooth on a serrated edge

- Every locking mechanism

- Every hairline crack

- Every alignment pin

Magnifiers help you catch what most people would never notice. Then you rebuild trays using reference sheets: diagrams, count sheets, surgeon preference cards, and sometimes those old, coffee-stained printouts that somehow survived three software “upgrades.”

Some trays have dozens of components. Some have hundreds. Miss one piece and you are not “almost done.” You are backtracking until the set is correct.

3. Sterilization: Science, Timing, Documentation

Different instruments require different sterilization cycles. You’ll manage:

- Steam autoclave loads

- Low-temperature cycles for heat-sensitive tools

- Chemical indicators

- Biological tests

- Batch numbers and load details

- Cycle validation sign-offs

This is where documentation becomes nonstop. Each load needs a traceable record for safety and compliance. And if anything looks even slightly off… A failed indicator, a questionable printout, a single parameter that did not hit what it should: the entire load is treated as non-sterile and gets reprocessed.

4. Storage and Case Picking

After sterilization, trays cool, get wrapped or containerized, labeled, scanned, and stored in the sterile core or a storage area that feels like a cross between a library and a hardware store.

Then comes case picking:

- Matching trays to the next day’s surgical schedule

- Pulling implants, loaner trays, specialty sets

- Checking expiration dates

- Signing off on case carts

- Running to the operating room when something is missing

Case picking is half organization, half sprinting. You’re always ready for the schedule to shift or a surprise add-on pops up.

5. Paperwork and Tracking: Boring & Necessary

This is the side the job descriptions tend to underplay:

- Decontamination logs

- Sterilization load records

- Missing instrument lists

- Repair notes for damaged tools

- Tracking data entry

- Expiration checks on peel packs

- Inventory updates

- Biological test filing

- Daily compliance checklists

- Relabeling items that get smudged for no reason

Plus, you’ll respond to emails. Messages from the operating room. Shift handoff notes. Incident reports if something drops, cracks, or gets compromised. The job is physical, yes, but the administrative side never really stops either.

6. Distribution and Fire Drill Mode

Surgeries rarely run perfectly on schedule, so sterile processing technicians bounce between tasks to:

- Deliver emergency add-on trays

- Locate a missing curette or clamp

- Re-sterilize a needed item quickly (facility policy determines what’s allowed)

- Replace peel packs that were opened but not used

- Track down “the one with the tiny hook at the end”

This role rewards people who can stay calm while moving fast. The operating room calls. You respond.

7. End-of-Shift Work

Before leaving, technicians typically:

- Refill packaging supplies

- Restock indicators and tape

- Check autoclave printouts

- Clean workstations

- Flag shortages for the supervisor

- Finish documentation from earlier tasks

It’s not the kind of job where you can simply clock out and vanish. A good tech finishes shifts strong and keeps the next shifts functional; that’s part of the job too.

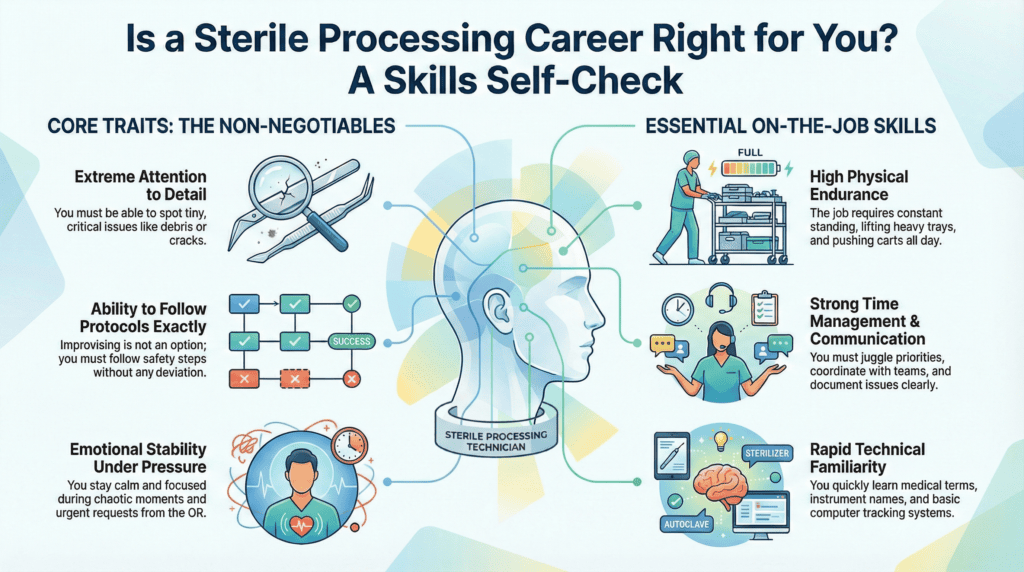

Skills That Make Someone Good at This Job

Some people thrive as sterile processing technicians because the details energize them. Others burn out because those same details never stop. The difference usually comes down to how you’re wired and which skills feel natural versus draining.

Core Skills

- Extremely Sharp Attention to Detail: You are spotting tiny issues that matter: a bit of debris stuck in a hinge, a cracked tip, a missing instrument, or a tray that is “almost right.” In SPD, “almost” can still delay a case or even send a tray back.

- Mechanical Intuition (How Tools Move): Medical instruments are full of tiny hinges, locks, ratchets, and alignment pieces. Nothing can feel stiff, loose, gritty, or misaligned. You need to know what it should feel like, and notice when it doesn’t in the slightest. Also when to flag something for repair.

- Ability to Follow Protocols Exactly: This is not a job where you improvise and just hope it works out. Steps exist for a reason: safety, sterilization standards, and compliance. Skipping a step or “doing it your way” can compromise a load.

- Good Time Management: You are constantly juggling priorities. What needs to be turned around fast, vs. what can wait. What does the next schedule look like? What’s about to hit the department from the operating room, now? Staying organized keeps you on track and from getting buried.

- Emotional Stability in Chaotic Moments: When the operating room is panic-calling for a missing item, stress can hit… Fast. The best sterile processing technicians stay calm throughout, they ask the right questions, and then move quickly to a solution; without spiraling or snapping-back.

- Physical Endurance: You stay: on your feet, lifting trays, pushing case carts, working in heat and humidity, and repeating precise hand motions all day. It is a really physical job… not “gym hard,” but steady, nonstop movement.

- Strong Communication: You are coordinating with the operating room, supervisors, and your own team. You also need to document issues clearly: what’s missing, what’s damaged, what was reprocessed, and what needs follow-up. Clarity prevents repeat problems.

Helpful Extras

- Knowledge of Surgical Specialties: When you start recognizing orthopedics needs versus cardiovascular versus general surgery, you’ll get faster and make fewer mistakes. You also learn which sets tend to be time-sensitive and which surgeons have more strict preferences:

- Laparoscopy Set (scopes/instruments used for minimally invasive surgery)

- C-section Set (obstetrics instruments for that procedure)

- Orthopedic Set (bone instruments, drills/attachments)

- A surgeon’s preference set (this tray is built the way a specific surgeon wants it)

- Familiarity With Medical Terminology: You don’t need to speak like a nurse, but knowing basic terms helps you understand tray lists, instrument names, and department requests without constantly asking for translation for: “We need the loaner ortho set for the add-on case. It’s IUSS.” (loaner set = vendor-supplied instruments; IUSS = immediate-use steam sterilization. *Depending on facility policy).

- Ability to Recognize Instrument Names Quickly: At first, instruments all look like “metal things.” Over time, their names start to click. That extra speed matters when you are assembling sets, hunting down a missing piece, or responding to a super vague request from the operating room.

- Basic Computer Skills: Most places use tracking systems to scan trays, log sterilization loads, document repairs, and prove compliance. You need to be comfortable with basic skills like scanning, data entry, or clicking through a few of the correct screens without panicking.

The Truth About the Pace

This is definitely not a “just show up and go through the motions” career. You are working inside a system that expects precision every single time. Even when you’re tired, even when the schedule changes, even when everything hits the department all at once.

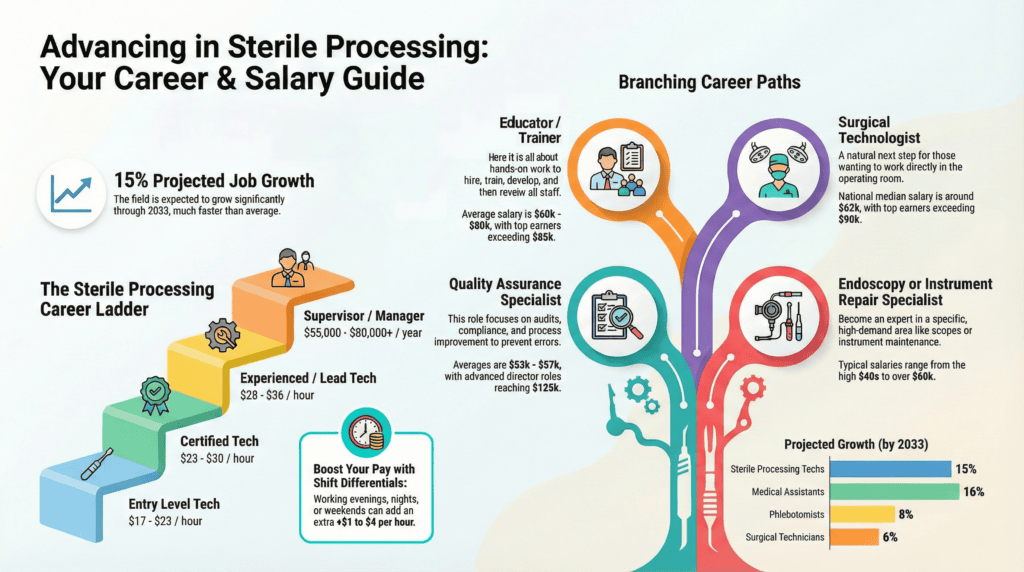

Pay for Sterile Processing Technicians

Pay is generally hourly, and it can be a lot different based on location, type of facility, your experience, and whether you work the “normal” hours vs the shifts nobody fights over.

According to statistics from the Bureau of Labor and Statistics “Medical equipment preparers” make between $22.35-$23.56 an hour (around $46,490-$48,990 per year).

Pay Per Experience Level*

- Entry Level: $17–$23/hour

Pay depends on where you are, what it costs to live there, and whether the facility will train a beginner or if they want someone who can hit the ground running. All these things factor into a sterile processing technician’s starting pay. - Certified Technicians: $23–$30/hour

Certifications like CRCST or CBSPD usually move you into higher pay brackets because they qualify you for more responsibility (Tech II roles, preceptor/trainer work, specialty assignments, etc.). Some facilities also only post certain jobs for “certified” technicians; and those listings tend to start with higher pay. - Experienced Technicians / Leads: $28–$36/hour

This is the pay you see when you’re the person everyone leans on. The one who can rebuild the complicated trays, catch a problem before the operating room feels it, and keep things moving when the whole day is, otherwise, a mess. - Supervisors / Managers: $55,000–$80,000+ Annually

The more volume and the more hours your department covers, the more likely it is the facility pays more at the leadership level. It’s the large hospitals or systems with multiple locations where you usually see that.

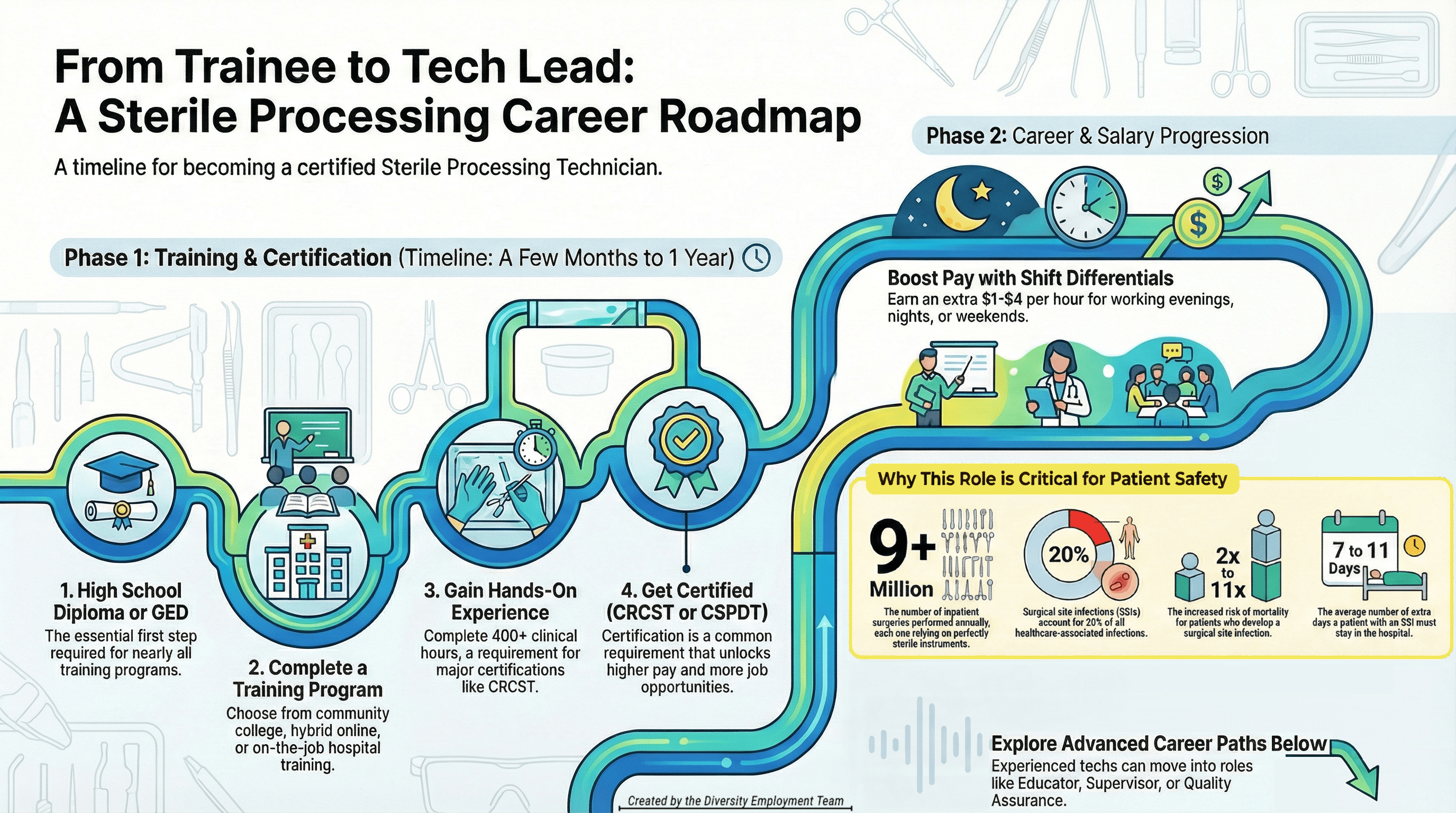

Shift Differentials and “Extra” Pay

Even when the base rate is decent, off-shifts are where the pay gets padded:

- Evenings/Nights: Commonly +$1–$4/hour extra; and some employers use percentage-based differentials for night shifts.

- Weekends: Often an additional variance, especially for the “hard-to-staff” shifts.

- Overtime: Departments that are short-staffed can offer regular overtime, which can push your yearly income up fast.

What Affects Pay the Most

- Where You Live (cost of living + local hiring competition)

- Facility Type (large hospital systems often have clearer pay steps and more advancement tiers)

- Certification + Job Level (Tech I vs Tech II/III vs lead)

- Specialty Workload (orthopedics, robotics, endoscopy, loaner/implant-heavy cases tend to raise expectations)

- Whether the Department is Truly 24/7 (more off-shift options = more gap pay opportunities)

Bottom Line: sterile processing pay is usually steady, and the most common ways people increase it are certification, experience, and working shifts that test what you can do.

*Pay ranges are estimates based on national wage data. Your pay may vary depending on where you live, who’s hiring, and which shifts you’re willing to work. Use these numbers as a starting point, they are not a guarantee.

Training and Certification: How to Actually Start

People seem to get overwhelmed here because online advice makes it feel like a maze. Truth is… It’s not. You pick a way to train, you get hands-on hours, and then you prove your skills with certifications.

1) Education

Realistically, you need a High School Diploma or your GED. Almost every single program and certification will want that first… Unless you find one of those rare “we’ll train you” openings with the right connections.

2) Training Program

There are a few common ways people get trained. It just depends on how fast you want to move, and what’s actually available near you:

- Community college certificate programs

Often the most straightforward option: structured classes, lab time, and a clearer pipeline into clinical hours. Some are designed to feed directly into local hospitals. - Online + in-person hybrid programs

These usually handle the “book knowledge” online (terminology, infection control, sterilization concepts) and then pair you with a clinical site for the hands-on portion. Great if your schedule is tight — but you still need real clinical time to become job-ready. - Hospital training programs (on-the-job)

Some facilities will hire you as a trainee and teach you internally. These can be a solid path if you find one, but they tend to be competitive because they remove the “school first” barrier. - Vocational schools

They can be faster and more “job-focused,” but their quality can vary…a lot. The main thing to check for, is whether they include a real clinical/externship part and prepare you for a certification.

Program Length: You should expect the program to last a few months to about a year. It’s all based on the format and the amount of hands-on training.

3) Clinical Hours

This is where the job becomes real. Clinical time is basically you working inside an actual sterile processing department (with supervision) until the workflow stops feeling foreign.

It matters because the SPD is hands-on: decontamination, assembly, sterilizer loading, documentation, tracking systems, case carts… You can’t learn the “feel” of it from a screen or textbook.

Also: If you’re aiming for CRCST (more below), hands-on hours are literally part of the requirement.

4) Certification (Strongly Recommended)

There are two major certification routes people take most often:

- CRCST – Certified Registered Central Service Technician

(HSPA – Healthcare Sterile Processing Association. *Formerly IAHCSMM)

CRCST requires 400 hours of hands-on experience in an Sterile Processing Department.

The Key Detail: Those hours can be completed before you test, or you can test first and finish the hours within six months (a provisional certification).

- CSPDT – Certified Sterile Processing and Distribution Technician

(CBSPD – Certification Board for Sterile Processing and Distribution)

CBSPD’s technician route accepts completion of a sterile processing training course (with a passing grade, of course) as one eligibility, and they also list work-experience as a pathway.

Real Talk: Plenty of employers will still hire trainees, but certification has become a common filter in job postings. They’re either required up front or required within a set time window after hire.

5) Apply for Jobs

Common entry points include:

- Hospitals

- Outpatient surgical centers

- Endoscopy centers

- Dental surgical facilities

And yes! You’ll find sterile processing technician jobs on our diversity job board, too.

Tools and Technology You’ll Use

Sterile processing is more tech-heavy than most people expect. A lot of the job is hands-on, but the equipment is what makes “clean” turn into “safe for surgery.”

The Main Stuff

- Autoclaves (Steam Sterilizers): You’ll be loading the trays. Then running steam cycles. You’ll check printouts/indicators to verify that cycle hit the right conditions and will document everything.

- Low-Temperature Sterilization Systems: They’re used for more sensitive items, certain plastics, scopes, and other heat-sensitive equipment, that are too delicate for high-heat steam. Different cycles. Different rules. Same pressure to get it right.

- Ultrasonic Cleaners: These are great for the spots you can’t really get to: hinges, serrations, little grooves. Vibration in a cleaning solution shakes debris loose. Mostly for the places you can’t scrub out by hand for certain.

- Washer-Disinfectors: No surprise, they’re just heavy-duty washers specifically made for cleaning surgical instruments right. They regulate cleaning so you are not relying on “scrub harder” as the entire plan.

The Systems That Track Everything

- Tracking Software: (For trays, loads, and instrument history) This is how facilities prove where an item has been: what load it was in, who assembled it, what sterilizer cycle ran, and when it expires.

- Loaner Tray Management Systems: Special handling for vendor sets and implants that come in for specific cases. Time-sensitive, paperwork-heavy… and a real headache when they arrive late.

The Inspection and Testing Gear

- LED Magnifiers / Lighted Inspection Stations: You use these to catch the tiny stuff: residue in hinges, hairline cracks, worn tips, or anything that looks “off” once you know what “normal” looks like.

- Instrument Testing Tools: (Examples: Sharpness testers, insulation testers) Some instruments need more than eyeballing. Testing helps confirm things like “is this still sharp?” or “is the insulation intact?” so the operating room is not discovering failures mid-procedure.

The Reality

Some equipment looks like it belongs in a sci-fi movie. Some looks like it has been surviving on sheer willpower since the late 90s. You’ll learn to work with both. And you learn fast which machines are reliable and which ones need a little extra attention.

Growth and Career Paths

Sterile processing technician jobs aren’t a one-lane road. Once you’ve got experience, a solid reputation, and a certification (or two), you can branch out in a bunch of directions. Some are still hands-on, others lean more on leadership, some are even more specialized.

Common Paths to Follow:

- Lead Technician: This is the “go-to” person. You’re the one people grab when something does not make sense, a set is missing pieces, or the pace starts getting shaky. You help newer techs, keep trays moving, and keep the standards steady even on the hectic days.

- Quality Assurance: This path is more about keeping the process itself tight: doing audits, compliance checks, tracking errors, making sure policies are followed, and catching repeat issues. Like, “why are these sets always coming back incomplete?”.

- Supervisor / Managers: This is where the job shifts from “doing the work” to “making the department run.” Staffing, scheduling, training, equipment problems, and constant coordination with the operating room all land on your plate.

- Surgical Technologist Training: Some techs use sterile processing as the bridge they’re looking for into the operating room. You’d already understand instruments and how procedures flow, so it can be a natural next step if you want to be closer to patients.

- Endoscopy Reprocessing Specialization: Endoscopes have their own rules, equipment, and standards. Specializing here can make you more valuable; and in some facilities, it comes with higher pay or more stable hours.

- Instrument Repair Technicians: If you’re the type who notices when a hinge feels off or a clamp doesn’t bite right, this path usually clicks. You’re more focused on maintenance, function testing, sharpening, and repair. This is the “why does this thing feel wrong?” side of the job.

- Educational / Training: Training new hires, running competency checks, building process guides, and teaching staff how to stay consistent. This is often where strong communicators end up.

The Advantage in Healthcare

Healthcare loves promoting from within when someone proves they’re dependable. If you’re the person who always shows up, stays accurate, and handles pressure without melting down, doors open… Sometimes, way faster than you’d expect.

The Real Pros and Cons

This job can be a perfect fit… or it can slowly drain your soul. People who like meticulously structured systems and detail-heavy hands-on work will excel the most.

The Pros

- High Job Security: Surgical services are a constant. When a facility has cases scheduled, sterile processing stays needed.

- Work Directly Impacts Patient Safety: Your choices affect infection control and procedure readiness, even if you never meet the patient.

- Real Respect (from the people who get it): People in the operating room understand quickly who’s solid and who cuts corners. Competent SPD techs earn trust.

- Predictable Steps Forward: You can usually see the path: Tech I → Tech II/III → Lead → Quality → Supervisor/Manager It’s all depending on the specific facility.

- No Years-long College Commitment: Compared to many other healthcare jobs, the training timeline is shorter and more affordable.

- Stable, Long-term Work: If you want consistency and a job you can build a life around, sterile processing technician jobs can be exactly that.

The Cons

- Physically Tiring: The job comes with lots of standing, lifting trays, pushing carts, repetitive hand work, and moving fast when the department is slammed.

- Decontamination: It can be hot, loud, and not fun. There’s high heat & humidity, you depend on your protective gear, and deal with constant noise… Oh, and you’re working with instruments that are genuinely dirty.

- Paperwork Never Fully Ends: There’s always something to log or track: load records, scans, labels, compliance checks, repair notes. It’s baked into how the department proves everything was done correctly… whether you love it or not.

- Time Pressures from the Operating Room: The operating room can go from calm to urgent in one minute. When you get a panic call, you’ll feel the urgency immediately to find, fix, and move what’s needed.

- Repetition (by Design): Keeping the routine is what keeps people safe. If you need variety all day long, you’ll definitely notice the sameness. A lot of this job is repetition. The real test is doing it the hundredth time with the same focus as you had the first time.

- Shift Work is Normal: Departments can be 24/7, early on you’ll usually get more nights, weekends, or holiday shifts on your schedule. That’s basically just how it goes in any job when you’re newer.

The Honest Takeaway

Some people thrive on the structure. Others simply don’t; ‘close enough’ habits don’t work in this field. Sterile processing has a very clear personality fit. If it fits you, it can be steady, satisfying work for a long time.

The Future of Sterile Processing Technician Jobs

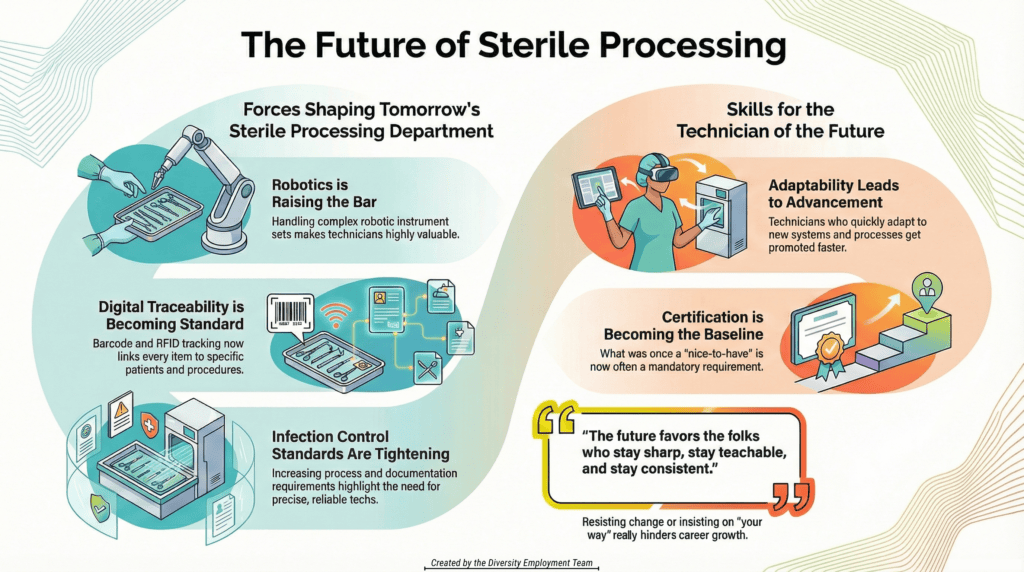

Sterile processing is changing fast, because surgery itself is changing. Procedures are getting more advanced, so the back-end systems that support them have to level up too.

What’s Propelling the Sector?

- Robotics is Raising the Bar: Robotic cases bring specialized instruments, more complex sets, and even tighter expectations around assembly and inspection. If you get comfortable with those trays, you become extra valuable quickly.

- Infection Control is Getting Stricter: Standards never loosen over time. Facilities keep tightening their processes, documentation requirements, and tech accountability. It highlights the importance of technicians who do things correctly the first time.

- Tracking Software is More Normal: More departments every year are moving toward full traceability. They’re digitally tracking everything using barcodes or RFID to link each item to specific procedures, patients, and staff.

- Surgical Volume Keeps Climbing: Across the country there are more procedures, more outpatient centers, and more cases per day. All of it increases the demand for a reliable sterile processing technician.

- Certification is Becoming the Baseline: In a lot of places, “nice to have” is turning into “required,” either before you get hired or within a set time frame after starting.

Real Advantages

Techs who can quickly adapt to new systems get promoted faster. The people who get stuck are the ones who don’t care to do better at work, resist change, hate documenting, or insist on doing stuff “their way.” For sterile processing technicians, the future favors the folks who stay sharp, stay teachable, and stay consistent.

Is This Career a Good Fit for You?

Sterile processing technician jobs are the kind where the “fit” matters more than expect. Being the loudest or the most outgoing doesn’t do much for you here. Being steady, accurate, and able to do the same important steps without letting your brain drift is what pays.

You’ll Probably Like It If You…

- You like detailed work and enjoy catching small things other people miss. You rather be correct than fast-and-sloppy.

- Stay calm when the pace goes from a marathon to a sprint. The operating room can shift your priorities in literally seconds. If you can handle that kind of urgency staying level-headed, you’ll do well.

- Do well with routine as long as it matters. A lot of SPD is repetition, yes, but it’s “repeatable on purpose,” like a safety checklist. If you can respect that, you’ll feel confident instead of bored.

- Prefer helping without being front-and-center. You’re part of patient care, just not the public-facing part. If you like being useful without needing recognition, this is a strong match.

- Want a real healthcare career without years of school. SPD is one of the more accessible routes into healthcare. It can get you working faster, and it still has room to grow.

Signs It Might Not Work

This job can feel restrictive if you need constant newness, hate rules, or get frustrated with documentation. Also, if you’re the type who wants to “figure it out as you go” instead of following a set process, SPD will clash with that mindset. Hard.

The Best Reality Check

Read real sterile processing technician job postings. Not just one, several. Look for the things those postings all repeat: certifications, paperwork requirements, knowledge of tracking systems, which shifts beginners work, the physical pace. Stuff like that. If you read through and think “that’s a challenge I’d take on,” you probably already know you’re in the right neighborhood. If they sound like your own personal nightmare, on the other hand, that’s a clear answer too.